Geomembrane Price Per Square Meter

Geomembrane as an indispensable material in many fields such as environmental protection, water conservancy, and construction, the price per square meter fluctuates greatly depending on the material type (such as HDPE, LDPE, PVC), thickness, and specific requirements of the project. Geomembranes of different materials have their own unique advantages and durability. It is important to consider the long-term performance advantages it provides, including chemical resistance, UV resistance, and resistance to mechanical stress while considering the price. Investing in high-quality geomembranes not only ensures efficient anti-seepage effects, but also promotes the overall sustainability of the project. Therefore, whether it is used for landfill liners, pond liners or other scenarios, understanding the cost per square meter is crucial to formulating an effective budget and choosing the product that best meets your needs.

Geomembrane Price Per Square Meter

Geomembrane as a key anti-seepage barrier material, it is indispensable in various engineering and environmental protection projects due to its excellent anti-leakage performance and long-term durability. Its price per square meter is affected by many factors, including the material selected (such as HDPE, LDPE or PVC), the specific thickness and the actual needs of the project.Designed to effectively block liquids and solids, the pricing of this material not only includes the cost of raw materials, but also reflects the advanced manufacturing process that can improve performance (such as UV resistance, chemical corrosion resistance and high strength). In projects such as landfills, reservoir construction and mining, investing in geomembranes is crucial. It can effectively prevent pollutants from leaking and protect groundwater resources.

Why Choose Us?

Applications

Bemax® HDPE geomembranes are versatile materials that have a variety of applications in several fields, particularly where liquid or waste containment is essential. Here are some of the most common applications:

Landfills: HDPE geomembranes are often used as liners in landfills to prevent leachate, a liquid that contains environmentally harmful substances, from contaminating the groundwater.

Ponds and Lagoons: They are used as liners in decorative ponds, fish ponds, lagoons, and artificial lakes to prevent water leakage into the ground.

Reservoirs and Tanks: They are also used to line reservoirs, tanks, and other storage facilities that hold water, other liquids, or even gases.

Canals: HDPE geomembranes are often used to line canals, ditches, or other waterways to prevent erosion and water loss.

Mining: In the mining industry, they are used to line tailings ponds and heap leach pads to prevent contamination of the surrounding environment.

Agriculture: In agriculture, they can be used in irrigation ditches, farm ponds, or even to line manure lagoons.

Construction: They can be used as a moisture barrier under concrete slabs or inside basement walls to prevent moisture intrusion.

Environmental Remediation: They are used in environmental remediation projects to contain contaminated materials or to prevent contaminants from spreading to adjacent areas.

Oil and Gas industry: They can be used for secondary containment around fuel storage tanks to prevent any potential leaks from contaminating the surrounding environment.

Aquaculture: In aquaculture, HDPE geomembranes are used to line fish or shrimp ponds to maintain water quality and prevent diseases.

Technical Parameters

Properties | Test Method | Test Value | Testing Frequency | ||||||

0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50 mm | 3.00 mm | |||

Thickness - (min. ave.) - mm | D 5199 | nom. | per roll | ||||||

Formulated Density (min. ave.) - g/cc | D 1505/D 792 | 0.940 | 90,000 kg | ||||||

Tensile Properties(1) (min. ave.) | D 6693 | / | 9,000 kg | ||||||

• yield strength - kN/m | Type IV | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Tear Resistance (min. ave.) - N | D 1004 | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Puncture Resistance (min. ave.) - N | D4833 | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Stress Crack Resistance (2) - hr. | D 5397 (App.) | 500 | per GRI GM- 10 | ||||||

Carbon Black Content (range) - % | D 4218⑶ | 2.0 -3.0 | 9,000 kg | ||||||

Carbon Black Dispersion | D 5596 | note (4) | 20,000 kg | ||||||

Oxidative Induction Time (OIT) (5) (min. ave.) | / | 90,000 kg | |||||||

(a) Standard OIT - min. | D3895 | 100 | |||||||

(b) High Pressure OIT - min. | D5885 | 400 | |||||||

Oven Aging at 85°C (5) (6) | D5721 | / | per each formulation | ||||||

(a)Standard OIT (min. ave.) - % retained after 90 | D3895 | 55 | |||||||

(b) High Pressure OIT (min. ave.) - % retained after 90 days | D5885 | 80 | |||||||

UV Resistance (7) | D 7238 | / | per each formulation | ||||||

(a) Standard OIT (min. ave.) | D 3895 | N. R.(8) | |||||||

(b) High Pressure OIT (min. ave.) - % retained after 1600 hrs (9) | D5885 | 50 | |||||||

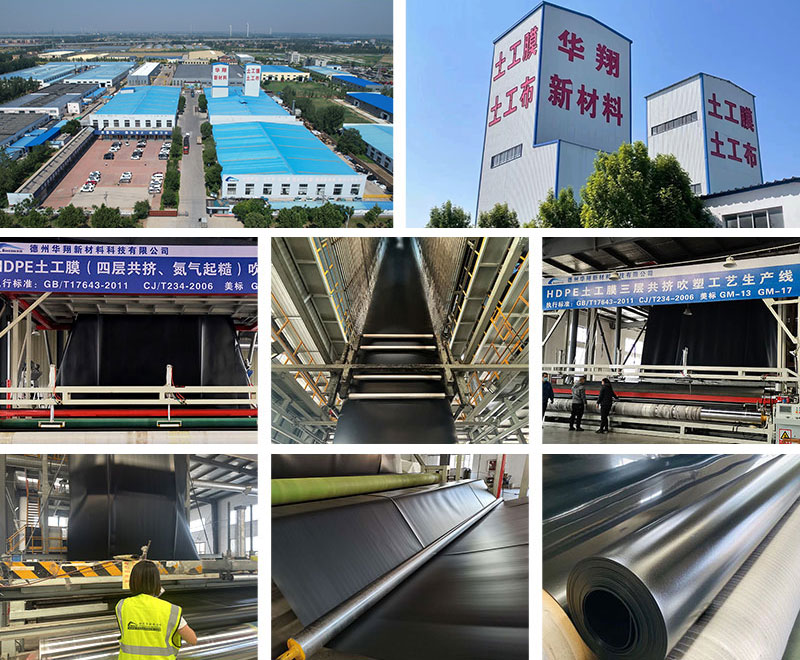

Bemax Geomembrane Factory

FAQ

Q: Are you a factory or a trading company?

A: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane and other products with more than 20 years of ISO9001 certification experience.

Q: Where is your factory? How can I visit?

A: Our factory is located in South head of Xingguo Street, Lingcheng District Economic Development Zone, Dezhou City, Shandong,China. You can take a plane to Jinan Yaoqiang International Airport, and then we can pick you up.

Q: Can I send samples before order confirmation?

A: Yes, if you need, we are happy to send free samples for your evaluation.

Q: How about the delivery time?

A: Generally within 5-10 days after receiving the deposit.

Q: Can you produce products according to customer requirements?

A: Of course, we are a professional manufacturer, welcome OEM and ODM.